The Precision of Dry Transfers vs Ordinary Water Slide Decals

Custom dry transfers are an excellent replacement for waterslide decals on product prototypes, scale models, labels for electronics and even details on musical instruments such as guitars.

Custom dry transfers are an excellent replacement for waterslide decals on product prototypes, scale models, labels for electronics and even details on musical instruments such as guitars.

Particularly in settings where objects are subject to scrutiny, they instantly improve results. Dry transfers are a better solution for the design community because they offer significant advantages over water slides in key performance areas.

How custom dry transfer decals and waterslides differ:

Water Slide Decals

- Potential water damage to the surface

- Yellowish carrier media shows on white

- Messy, delicate, difficult to handle

- Unable to print in true white on inkjet

- Difficult on curves; can wrinkle & lose shape

Dry Transfers

- No damage to the application surface

- Work without complications on white surfaces

- Ease of handling, more durable

- Allows for true, pure white unlike inkjet printers

- Ability to follow curves without quality loss

Dry Transfers Have Visual Advantages Over Waterslides

No matter what your project, you’ll have better-looking results when you switch from water slide decals to dry transfer decals.

The improved appearance also comes with several application advantages:

-

- First and most importantly, some inkjet printer ink is water-based which can cause the ink to run.

- The other complication with water slide decals is the yellowish tint of the carrier media. This is instantly visible on white surfaces and can diminish the clarity and sharpness of edges and lines.

- With water slide decals, some designers have even gone as far as concocting diluted vinegar treatments to overcome some visual disadvantages. But the results can be iffy and far from reliable. With the better option of dry transfers in these same situations you no longer need to resort to improvised workarounds.

Our custom dry transfer stickers (we prefer calling them decals because ours are not sticky) are easier to handle, more convenient to apply, do not turn yellow over time and do not damage the surface you are applying them to. We create them from your digital files using a special ink backed with adhesive. They are delivered on transfer paper that allows you to rub them onto any surface without water or solvent.

Custom Dry Transfer Decals Provide Surface Protection Advantages

If you are sampling up a prototype, creating a custom display object or working on a hobby project, dry transfers provide surface protection not possible with products involving water.

Dry transfer decals also bring an appearance on par with professionally manufactured products.

Especially valuable when there are tight deadlines, dry transfers reduce the variables connected to an application. These include fewer complications and no damage to wood, wall paint, metal, glass, plastic, and other labeled surfaces.

For custom lettering decals, logos, graphic elements, and any other applied surface enhancements, our custom dry transfers are ideal design solutions.

Even fine print remains crisp and clear and we’re an excellent replacement for vinyl lettering, Letraset and ChartPak rub-on letters.

With overnight delivery service, dry transfers are now easily available in quick turnaround situations. Also, because they are created directly from your digital files and color-matched with Pantone palettes, you are assured of receiving back exactly what you designed with all of its needed detail and nuance.

Dry Transfers Have Advantages for Application and Ease of Use

The application process for dry transfers is direct and straightforward. Other than a steady hand and a focused approach, little else is needed.

They work equally well on models that are 3D printed or molded mock-ups and are fast and easy to apply.

- Place where desired

- Rub down with the burnisher (provided) and they are affixed and semi-permanent.

- Just add a clear coat of lacquer to make them permanent.

Dry transfers can be applied successfully to any smooth surface without damage nor water-related complications.

Better still, they are free from carrier media and there is no need to cut around the edges of the decal.

The adhesive only exists under the image – where you need it. This saves time and reduces the potential for mishaps when applying them.

Neither solvents nor treatments are needed and one of the greatest advantages is no drying time is required. Your piece is ready to use or display the moment you finish applying the dry transfer onto any surface . For applications requiring greater durability, applying a coat of lacquer is an additional option.

Dry Transfers Have a Precise Look and Perfect Results – Instantly

The most essential measure of success for any project is a visually precise and accurate appearance. With dry transfers, successful outcomes are more likely than with water-slide decals and the process for getting to a final piece is more reliable and less left to chance.

If the model or prototype you’re creating will be in use for an extended time or is subject to handling, dry transfers are more durable than water slides. They are simply more stable and longer-lasting. When your projects call for uniqueness and flair, our custom dry transfers are available in a broader range of interesting appearance options including both metallic and custom foil transfers.

Each color is backed with white to ensure a consistent & uniform look.

In side-by-side comparisons with water slides, most industrial designers agree the dry transfer achieves a more permanent and precise look – with the quality and appearance of final manufactured products.

They are available overnight, have fewer complications, ensure a more precise appearance and are much easier to use. Deadlines and changing specs can add enough stress and complication to your workflow.

The advantage of dry transfers can remove one variable from your list and help you achieve better results right away!

If you are planning a project or have a new concept underway right now, it’s a great time to switch from water-slide decals to custom dry transfers. At Image Transfers, we’re ready to help you develop a successful final product that will win kudos and compliments when it is presented or displayed. We will enhance the appearance of your project providing a finished and tangible look and feel.

hi i am looking for some decals to be made of my speaker logo and writing can i send you a picture to see if this is possible?

Raju, Yes. Email to luann@imagetransfers.com. Best file format is vector art. If your file is not in that format we can create it for an additional charge. Transfer pricing is published right on our website. We look forward to hearing back from you.

I am looking to have made custom police decals for a 1:24 scale die cast Ford Explorer. Do you make decal for these types of applications?

Nick, We are probably not the right source for you for this project. Yes we can probably create these transfers but we don’t have any “off the shelf” product. Everything is custom so we would need to create that art, and I assume it will be multi-color? Our price structure usually fit the budgets of Industrial Designers creating prototypes. Usually most model makers don’t have these type of budgets. Please review our pricing published on our website. If these costs work for you please get back in touch. As an alternative may I recommend you specifically google exactly what you are looking for to get a source.

Do your dry transfer decals adhere to unglazed ceramic?

Michael, I can’t say if any of our clients have tried to apply our transfers to unglazed ceramic but they have been applied to a lot of different substrates including “rocks.” The transfers are lacquer ink with lacquer adhesive. Since adhesive is only on the image area, there will not be any adhesive residue. I would “assume” they will work fine. If you want more info just email us at art@imagetransfers.com Thanks for your inquiry.

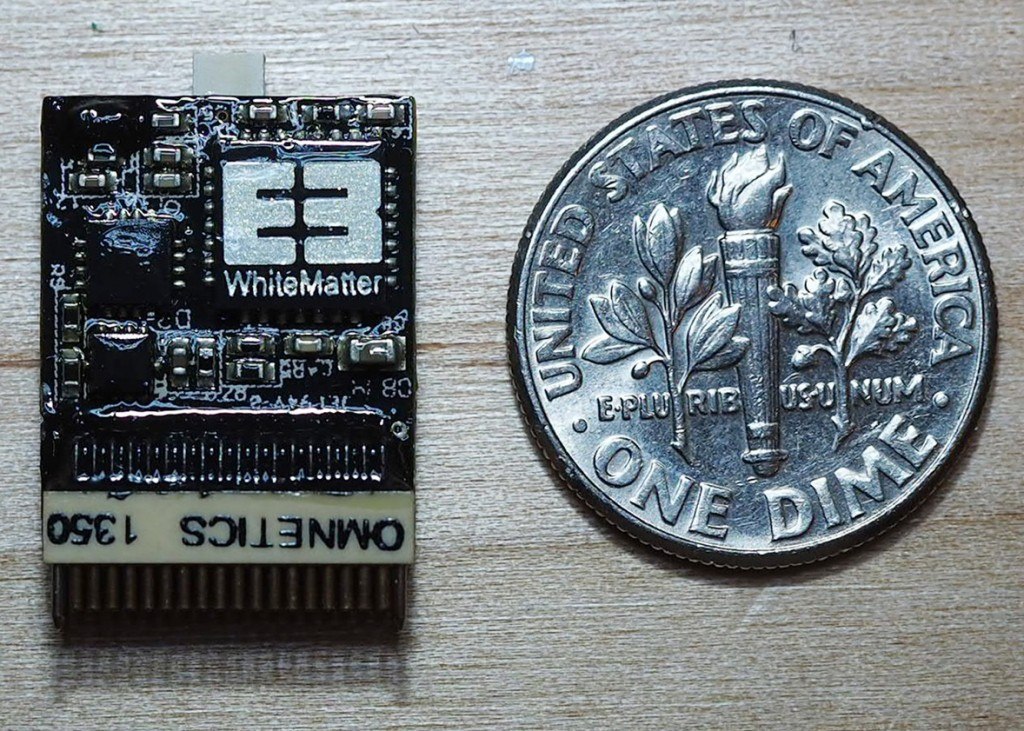

Can you produce dry transfers with a complex color pattern such as multiple shades of blue, red and black in an area the size of a dime?

Our production artists are very talented but it would be difficult to determine if we can produce this with just a description. Is it possible to send a visual of the art to our email address at art@imagetransfers.com? We have created custom dry transfers from complex art and multi-color but need more information before we can say yes to this project.

Can your decals be lacquered over with nitrocellulose?

Thank you!

Bill, Sorry for any delay in replying. Our transfers are lacquer ink with lacquer adhesive. Since adhesive is only on the image area after applied the artwork will look like it is printed right on your substrate. We are not sure if our transfers can be lacquered over with nitrocellulose. We would be happy to send you some samples of our transfers to test on your end if you want to email us your snail mail address. Please reply to art@imagetransfers.com if you are interested. Thanks!

Hi I need decals made for some O scale trains. The decals would be yellow and applied to a medium blue plastic shell. They would just say the road name (Granite Gorge & Rockville) and numbers. I can send you exactly what I want. Thanx, James

James, We would be happy to help you with this project. Our pricing for 1/color transfers is published on our website and goes by “size area” so we would gang-up/repeat your copy to fill a letter size since that is the smallest size we offer. Letter 1/color is $175.00. It seems your artwork would be simple so we can probably set that for you at no additional charge. If you would like to move forward just email us at art@imagetransfers.com with more information. We look forward to hearing back from you.

If I apply one of your dry transfers to my car, will it survive going through an automatic car wash

Bill, Our transfers are lacquer ink with lacquer adhesive. They are not suitable to apply to a car. They are mostly used by Industrial Artists creating prototypes. You might want to check into vinyl lettering. Maybe “google” vinyl sign companies. Vinyl is used on indoor and outdoor signage and might be the right solution for you. Good luck.

Can dry transfer decals be applied to a gloss black motorcycle fender

Jim, Our transfers are lacquer ink with lacquer adhesive. They certainly can be put on a black fender, and since adhesive is only on the image area, after applied it will look like the art is printed right on the substrate. But if applied for a permanent solution you would have to coat the transfer w/clear lacquer spray. Our transfers are usually used for prototypes. If you want more information just get in touch. Thanks for your inquiry. Luann

Hi

Looking to av a dry letter transfer made to replace the originial 1 that as worn away on the side of a old locomotive

The transfer says

elemore

Colliery

Any help or advice would be much appreciated

Thank you

Tony, We can certainly create a custom dry transfer for you but we would need “artwork” for the elemore colliery image. If you needed us to create artwork for you that would be an additional cost. Pricing is published right on our website. We have no off the shelf products so we are not sure our costs would fit your budget. A one color transfer is $175.00 and artwork would be additional. If you wanted to move forward please send us a visual of the logo you need and we can get back to you with a cost for artwork as well. Thanks for your inquiry.

Hi my name is James services 321 I am looking to possibly buy a decal it’s for the large Phoenix Dry Max dehumidifiers

James, I don’t think we are the right source for you. Out transfers are usually used on prototypes. You might want to specifically google exactly what you need. There maybe some off the shelf decals available for you. Good luck.

We sell hand poured candles in glass or ceramic jars. Would your product work to apply our label. Currently we use clear stickers and are wanting a more ‘screenprint’ look.

Vicki, We have had a client use our transfers for this exact purpose in the past. Our transfers are lacquer ink with lacquer adhesive. Since adhesive is only on the image area, after applied it will look like your logo art is printed right on the glass or ceramic. We just want to detail that the transfer can get scratched if someone tries to do that but we have a transfer on our glass door for years with no issues. Best way to move forward is to gang-up your logo into one of our artboard size areas because that is how our pricing is structured. We need vector artwork. If you have further questions just email back or call the studio at (212) 928-7987. We hope to work with you on this project.

What kind of machine do you use to print on?

That puts down white first

Tina, We don’t use a machine. Our transfers are produced by production artists. All our transfers are custom with clients usually supplying the art but we can create artwork for you as well. Pricing is published right on our website and cost are by artboard size area. Get in touch if you have more questions.

Is it inkjet or silkscreen ink?

If it’s not a printer of some sort then your artist are coloring by hand or painting by hand and that seems not to be very cost effective.

Tina, We pride ourselves in very high quality custom dry transfers. In order to provide this product we have one production artist working on one transfer until it is completed and packed up for FedEx. We have no off the shelf product or do anything with a printer. Most of our clients are Industrial Designers creating prototypes. The final prototype has to look perfect for marketing purposes. Some projects have smaller budgets. We suggest those clients gang-up more art to make the transfers more cost efficient or search for an off the shelf solution. If you have more questions just get back in touch. We hope you find the perfect solution for your project.

I liked that you said that there are different kinds of decals that can be used on your vehicle to custom the auto body to promote business. I have been thinking about using my vehicle to advertise my business. I will be sure to go to a professional for this service, however, in order to achieve quality results.

Ashley, Our transfers can certainly be used on a number of different substrates. They are really not suitable for automobiles. First because of the size needed to advertise on a vehicle. Second because we describe our lacquer transfers as semi-permanent unless coated with a clear lacquer spray after application. Vinyl sign cutting will probably be more suitable for you or even “google” vehicle wraps which have come down in price and can be quite vibrant when applied. If you have further questions please feel free to call the studio at (212) 928-7987. Thanks for your inquiry and best of luck with your project. Luann

Nice Page

Can you send a sample of dry and wet with this product name.

Pet Sheet, using Papyrus 3/4 to 1″ height.

and price per ea.

AudioVac Mfg

4026 Braelan Ln

Hazel Green WI 53811

Tom, We can certainly send you samples of our transfers but they would be of our logo art. If we did something specific, like you are asking, that would be a job. We have decided that in order to send samples we would need your UPS or FedEx Account to ship on. Putting samples into snail mail usually don’t make it into our potential client’s hands. Feel free to email us at art@imagetransfers.com or call studio number at (212) 928-7987 if you want to discuss further. Thanks for your inquiry. Luann

I have a white logo I’d like to apply on a black guitar headstock. Your dry decal application would thus be perfect. Do let me know how to proceed from here.

Patrick, to proceed we just need a vector file of your logo art. An Adobe Illustrator file is perfect. You should scale your logo to the size you need and gang-up/repeat the logo nicely spaced on one of our artboard size layouts. The smallest size transfer we offer is letter. Pricing is published on our website. Letter in 1/color is $175.00. You can even order through the website if you can supply this type of file. Create an account, login, drag & drop, choose white, choose your FedEx and get an instant receipt.

If you need help with creating a vector file that would be additional and we would need to see the type of file you currently have to give you a quote.

You will be quite pleased with our transfers compared to a water slide. Our ink is opaque, application is easy – just rubbing through the clear slick with a burnisher we supply and there is no adhesive residue since adhesive is only on the image area.

Let us know if you have further questions. We hope we can work on this project with you. Luann

Hello Luann, I originally wanted to transfer a photo of a young child onto a rock to honor his memory. An Etsy rock artist suggested she makes water slides. But she now says her water slides become too delicate if they are more than two inches, as explained on your website!

I am so disappointed after I bought rocks and varnish materials to smooth the rock surfaces.

Should I look into your dry transfers?

My photos are all about 4 – 4.5 inches tall.

Thank you.

Minlin, We can do custom dry transfers that can be applied to rocks. We had another client that did just this for a walkway, in a park, for directions. But we need vector artwork for our process. We don’t know what type of files you have for the young child. If you are asking for a 4/color process image (like a photo) we can’t help you. If this is just a silhouette in 1/color we can do that. After applied you will need to coat the applied dry transfer with a clear lacquer spray. Please reach out at (212) 928-7987 if you would like to discuss this project further. Thanks for your inquiry.

Looking for direction on how I can print my own dry rub furniture transfers. Several companies make these in mass so I know its possible I just want to create my own. Any direction you might have would be appreciated.

Cyndi, We realize you might want to try printing your own dry transfers but it is a very involved process, strict OSHA rules for studio, artist skills, inks, adhesive, etc. We really can’t give you any direction on helping you move forward with this. Our production is a propriety process that we perfected after many years of research. Maybe you should “google” off the shelf furniture transfers and possibly get a source that you can work with. We appreciate your inquiry and wish you success in your endeavors.

Can these be used on cups and coffee mugs that will go in the dishwasher?

Faith, Thanks for your inquiry. No our transfers can’t be used for cups that go in a dishwasher. Our custom dry transfers are mostly used for prototypes – products that are not quite developed yet but clients want them to look realistic and review any issues with that development. We would recommend you look for a promotional product company that can create these for you. Best of luck with finding the right source.

How hard is it to remove dry transfers?

Joe, Thanks for your inquiry. Our transfers are lacquer ink with lacquer adhesive. We have had clients remove them in a few different ways. We would recommend testing any of these methods in an inconspicuous spot just incase. First if the transfer is not on the substrate too long you can probably tack it off with painter’s tape. Next option would be a Bestine Solution found in Home Improvement stores or Amazon. Last resort would be lacquer solvent since they are lacquer ink. Some clients have even painted over them if that is an option because they are only the thickness of the ink. If you want to give us more details about your actual project maybe we can advise you further. We hope to work with you on a future project. Thanks again, Luann

Would like to speak to somebody about your dry transfer decals for my guitars that I am building I like they R In the circle that you have Would like to have serial numbers around perimeter A telephone number is 3216964576

Kevin, Thanks for your inquiry. I will give you a call shortly. Luann