Letraset Instant Lettering was a mid-20th Century alternative to Letterpress Typesetting

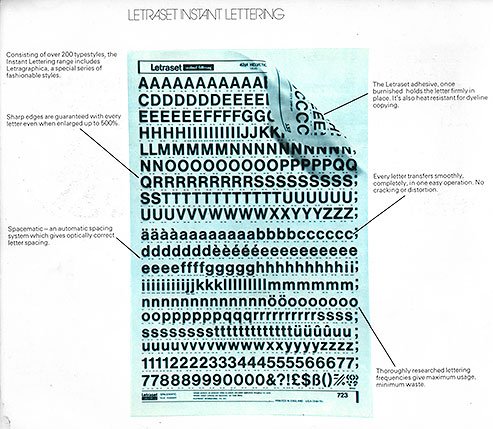

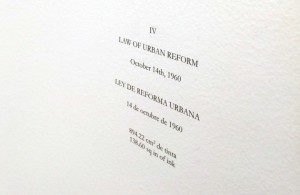

The original Letraset System comprised a library of transfer sheets that were pre-printed with fonts of alphabet letters. The majority of these typeface letter sheets were in sizes and fonts that were most frequently used – nowadays called true-type styles and point font sizes. Each letter was individually transferred to drawing paper, or any other smooth surface, by the use of water in combination with their patented transfer frame. By this means, words, captions, notices, or designs could be built up, relatively simply and quickly. It became an alternative to phototypesetting back in the 1950s. No skill was required, and the result is comparable with the best quality printing and typesetting available at the time.

The original Letraset System comprised a library of transfer sheets that were pre-printed with fonts of alphabet letters. The majority of these typeface letter sheets were in sizes and fonts that were most frequently used – nowadays called true-type styles and point font sizes. Each letter was individually transferred to drawing paper, or any other smooth surface, by the use of water in combination with their patented transfer frame. By this means, words, captions, notices, or designs could be built up, relatively simply and quickly. It became an alternative to phototypesetting back in the 1950s. No skill was required, and the result is comparable with the best quality printing and typesetting available at the time.

Before Image Transfers Inc. and Before Personal Computers … There was “Instant Transfer Lettering”

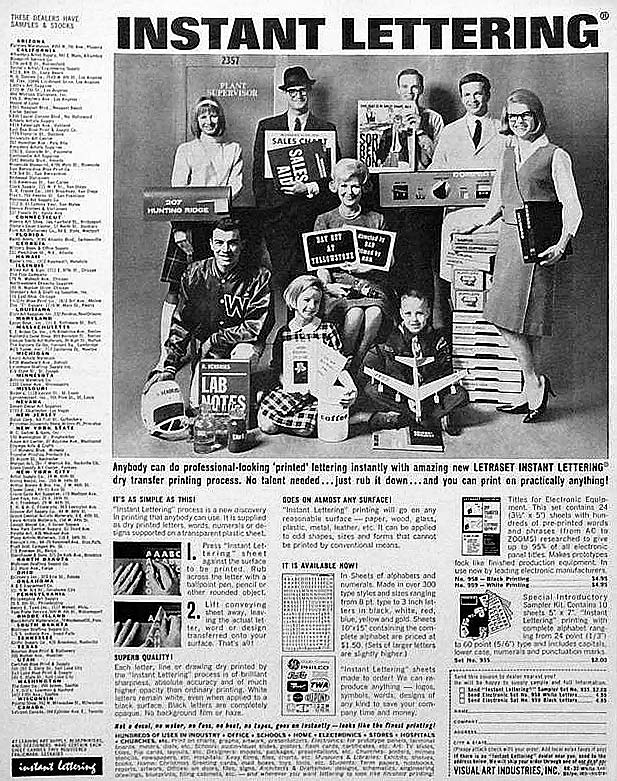

In 1957, an entirely new process to achieve the same results was conceived whereby no water or frame was necessary. The transfer was made merely by pressure applied to each letter with a pencil or ballpoint pen. After extensive research and development on this new “dry” process, a complex manufacturing plant with facilities for the production of the Company’s own inks and adhesives came into operation in 1960. The new product was named Instant Transfer Lettering and, being suited for the North American market, was first introduced there.

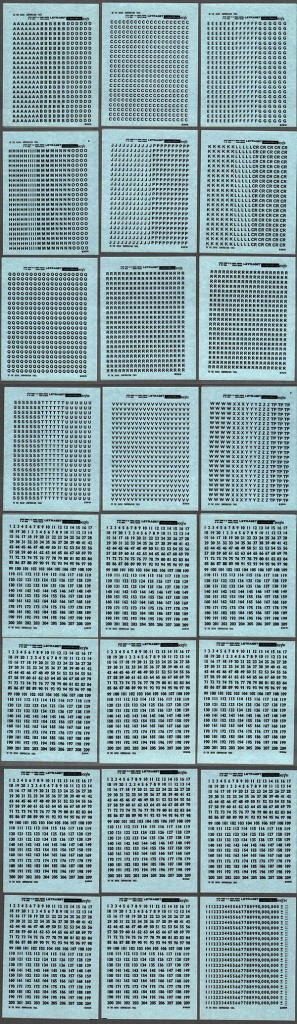

All Letraset sheets were expendable – letters could only be used once – and were supplied from a library range of over 2000 items. By 1963, Instant Transfer Lettering accounted for the majority of the company’s business, which exported and distributed its product internationally to over 70 countries.

The Letraset Company

The rapid rise of Letraset Limited in the 1960s and 1970s is one example of how a company carefully evolved its new technology into a profitable manufacturing and worldwide export trade business. This began a DIY typography revolution that made it easy for anyone to display typefaces

The rapid rise of Letraset Limited in the 1960s and 1970s is one example of how a company carefully evolved its new technology into a profitable manufacturing and worldwide export trade business. This began a DIY typography revolution that made it easy for anyone to display typefaces

Their product was a new type of pre-printed sheets of rub-down letters based on a sticky adhesive that was applied with pressure and without the need of water or any intermediate silkscreen.

The world of advertising and marketing was transformed entirely once it was introduced onto the scene in 1959. What we know as dry transfers today would not be around if it weren’t introduced by John Charles Clifford “Dai” Davies and Fred Mackenzie, who carried out the task.

It all started in 1956 in London when Dai Davies thought of using transfers to replace letterpress, which was the primary form of impressing letters at that time, according to John A. Chudley in Letraset, a Lesson in Growth (Business Books, London. 1974).

What they set out to create started out as waterslide decals that have been used since the 1860s but as lettering. Soon it evolved into the more established dry transfers.

“At Dai’s insistence we were striving for a level of quality in printing that was virtually unknown in the commercial screen printing world, and by painstakingly meticulous methods in the preparation of the artwork and careful construction of special-purpose printing machines we were able to achieve a standard that did much to help keep us in the number-one market position. A further advantage we gained from self-reliance was a greater knowledge and control of our production processes. “ (ibid., Chapter 3, p.18)

In order to launch their sheets of rub-down letters, Mackenzie and Davies borrowed money in 1959 from John Chudley, the third partner to the company.

The product remained water-based until Instant Lettering was officially patented in 1962.

Letraset sheets were sold exclusively– you had to know someone to get them – and the company’s form of “Instant Lettering,” or rub-on transfer lettering, took the world by storm once it was perfected.

Letraset sheets were sold exclusively– you had to know someone to get them – and the company’s form of “Instant Lettering,” or rub-on transfer lettering, took the world by storm once it was perfected.

In a very short time, the company went public in 1963. Mackenzie sold his shares and left the company. In the same year, the company also acquired Kippax Pneuminor Silkscreen Press. They kept building their business, got into more printing sheets of transfer letters, but this time with color.

The team soon set up their operation in Ashford after purchasing a rotogravure press. When the business kept growing, the company bought a factory in Italy. The factory gave them more freedom by using litho presses for printing transfers.

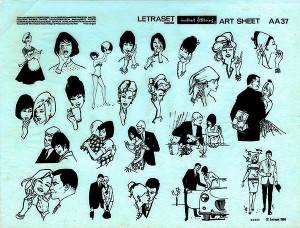

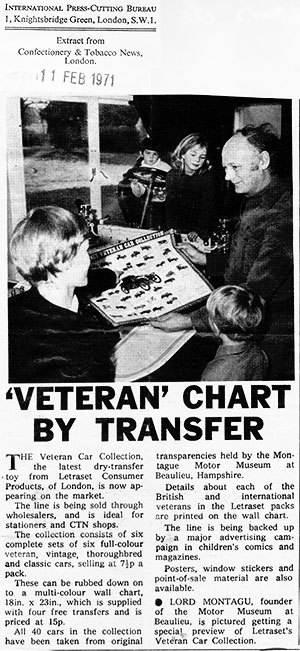

The company’s main draw was its product line of Instant Lettering typefaces, which was originally made through a process of monochrome silkscreen printing. However, the company was looking for more ways to stay relevant in the business with new ideas for its rub-ons. It started to make children’s products, but their monochrome transfers weren’t kid-friendly enough, and the company made a shift to fully colored waterslide transfers.

The company’s main draw was its product line of Instant Lettering typefaces, which was originally made through a process of monochrome silkscreen printing. However, the company was looking for more ways to stay relevant in the business with new ideas for its rub-ons. It started to make children’s products, but their monochrome transfers weren’t kid-friendly enough, and the company made a shift to fully colored waterslide transfers.

Instant Transfers offered a wide range of typestyles and typefaces, including “Letragraphics.” It also produced a great collection of rub-on numbers and symbols.

Here’s a fun fact: the company used the now iconic Lorem Ipsum filler text in its advertising. And though it may not have invented it, the company definitely had a hand at making it popular.

By 1968, the company migrated to making Action Transfer sets, a collection of printed rub-down transfers, according to Action-Transfers.com. Its first set was the “Animals of the World” for children. There was no mention of “Instant Pictures” after this. For strategic reasons, the company did not want to be mixed up with Polaroid.

Eventually, the company was sold to Tom Salter in 1978 for £1 million. Letraset Consumer Products began to fizzle, and Salter decided to work under his own name instead, Action Transfer Products (part-owned by Salter) which produced sheets of small rub-on art images, was run by John Hunt, who left to form another company around 1981.

Salter went belly up in 1983 and declared bankruptcy. Peter Pan Playthings bought the assets to the company in 1985. Not in the custom rub on transfer business, Peter Pan also declared bankruptcy soon thereafter. Acorn Printed Products, the company Hunt went on to co-found, own the rights to Action Transfers. Acorn had exclusivity to produce print transfer sheets once Salter closed his business.

Salter went belly up in 1983 and declared bankruptcy. Peter Pan Playthings bought the assets to the company in 1985. Not in the custom rub on transfer business, Peter Pan also declared bankruptcy soon thereafter. Acorn Printed Products, the company Hunt went on to co-found, own the rights to Action Transfers. Acorn had exclusivity to produce print transfer sheets once Salter closed his business.

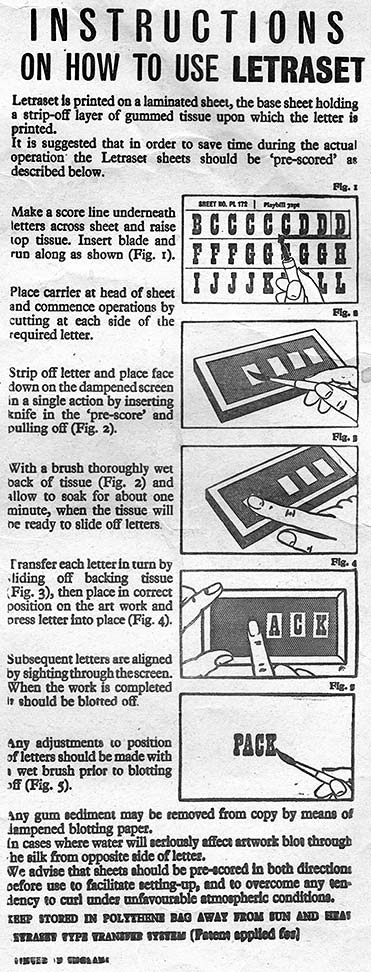

Here’s how Instant Lettering works (original directions from the manufacturer)

- Light adhesive to hold the transfers onto the carrier sheet (Carrier Layer Adhesive);

- Strong adhesive to fix the typeface onto the recipient surface (Surface Adhesive).

That’s the main event. Here are the other ingredients:

- You need a protective tissue that the surface adhesive can’t stick to.

- You need a carrier sheet that’s transparent, so you can see the transfers through it (and see what you’re doing).

- The carrier sheet needs to respond to pressure (and heat) by buckling, so that the transfers, which do NOT buckle, are forcibly detached when it does buckle.

- You need to PRINT the Surface Adhesive onto the bottom of the transfer image (or its halo), so that you don’t get nasty sticky glue anywhere else.

- Job is done.

How to Use Instant Rub Down Lettering

Original directions from the manufacturer:

Custom Letraset is printed on a two-layer sheet. The top layer of thin, gummed tissue carries the letters. To strip off letters, cut a score line through the top tissue under each line of type and insert the tip of a cutting tool to raise the edge. This is done by running the blade along under the scored line, as shown. Cut both sides of tissue required and from loose edge peel off…

- …place letter typeface down on moistened silk on the back of the frame. Thoroughly wet tissue and let soak for 1 minute. Now slide away tissue…

- …letter remains on screen. Now turn over the frame — a letter can be seen to align on artwork. Press down on letter through silk and lift away frame. Adjust letter if necessary with a blunt point — blot off.

It would be difficult to find them today, perhaps on eBay, but even if you did they’d probably be collector’s items. Nowadays technology has been improved and manufacturing happens in smaller custom batches.

About Image Transfers

Our company, Image Transfers, has taken this technology to the next level. In our Garnerville, New York studio, all we do are custom dry transfers, we’ve been in business since 2008 and have great customer reviews from our clients. Our process of making dry transfers differs considerably from “Instant Lettering”. We don’t mass produce transfers. We don’t manufacture them with machines. Production artists are assigned jobs before noon, which is our deadline in-house. Our process is that one production artist is working on one dry transfer until it’s completed and packed up for FedEx. This process continues all throughout the day. Our turnaround is quick with most work coming in before noon and going to FedEx that evening.

Our company, Image Transfers, has taken this technology to the next level. In our Garnerville, New York studio, all we do are custom dry transfers, we’ve been in business since 2008 and have great customer reviews from our clients. Our process of making dry transfers differs considerably from “Instant Lettering”. We don’t mass produce transfers. We don’t manufacture them with machines. Production artists are assigned jobs before noon, which is our deadline in-house. Our process is that one production artist is working on one dry transfer until it’s completed and packed up for FedEx. This process continues all throughout the day. Our turnaround is quick with most work coming in before noon and going to FedEx that evening.

Since transfers are produced by “artists” the colors are matched exactly, the custom rub-downs are created as perfectly as we can manage, and the final product is beautiful. Our rub-down letters are “fresh,” and they are much easier to apply than Instant Lettering ever was.

Since transfers are produced by “artists” the colors are matched exactly, the custom rub-downs are created as perfectly as we can manage, and the final product is beautiful. Our rub-down letters are “fresh,” and they are much easier to apply than Instant Lettering ever was.

Another difference is we produce our transfers on a clear slick, unlike Letraset’s translucent slick. This production upgrade makes it even easier to apply your artwork. We even supply a burnisher with every order.

The best way to get a project to us is to visit our website at ImageTransfers.com. You will find our website “user-friendly.” New clients need to create an account. Returning clients just need to log in. Once you’re logged in, it is easy to place an order. Clients just need to drag and drop art, choose color and quantity, choose the FedEx option, pay online and get an instant receipt.

The best way to get a project to us is to visit our website at ImageTransfers.com. You will find our website “user-friendly.” New clients need to create an account. Returning clients just need to log in. Once you’re logged in, it is easy to place an order. Clients just need to drag and drop art, choose color and quantity, choose the FedEx option, pay online and get an instant receipt.

In-house, we get a notice that there is an order waiting to be processed. The project is assigned to an artist and put into production. Jobs are assigned all day long. A final quality check is performed before the dry transfers are packed up.

Our Letraset dry transfer quality is guaranteed. If you are ever unhappy with our product we will do it over at no charge. Our clients will receive a tracking number so they know when they will receive their custom dry transfers.

Our Letraset dry transfer quality is guaranteed. If you are ever unhappy with our product we will do it over at no charge. Our clients will receive a tracking number so they know when they will receive their custom dry transfers.

Since our staff is made up of visual artists, if clients ever need artwork created we can do that, for an additional fee. We can start with a photo or specs and will create vector art, send a PDF visual for approval, and get the project into production.

Our studio is open Monday through Friday from 9 a.m. to 5 p.m., and we are very customer service-oriented. It would not be unusual for someone to answer the studio number after hours or send back an email reply over the weekend.

Don’t miss out on your totally unique, custom dry transfers. For more information, please visit ImageTransfers.com.

Hello there!

I’ve stumbled across your website here after thinking about Action Transfers that my Dad first started to buy me as a 10 year old in 1976. I thought they had become non existent over the years since the days of Letraset diminished.

Do you still make them? I’m hopeful you will say yes?

Do you have any samples that you could spare so I may revisit my childhood again?

I hope you are still manufacturing them in some way, shape or from!

Thank you and kind regards everybody

Chris, Thanks for your inquiry. Unfortunately we do not stock any off the shelf transfers, like Action Transfers. All our transfers are custom with clients supplying artwork and one of our production artists working on the project until it is packed up for FedEx. Maybe you should “google” specifically Action Transfer to get some sources? Or try off the shelf transfers might get you in the right direction. If you ever need custom transfer we are certainly the source for you. Best of luck in your search.